Cantilever racking is a type of warehouse storage system that is designed to store long, bulky, or irregularly shaped items. It is especially suitable for storing goods that cannot be stored on pallets, such as lumber, pipes, furniture, or machinery parts. In this article, we will explain what cantilever racking is, what are its advantages, how to choose the right system for your warehouse, and how to install and maintain it. By the end of this article, you will have a comprehensive understanding of cantilever racking and how it can improve your warehouse operations.

What is Cantilever Racking?

Definition and Components

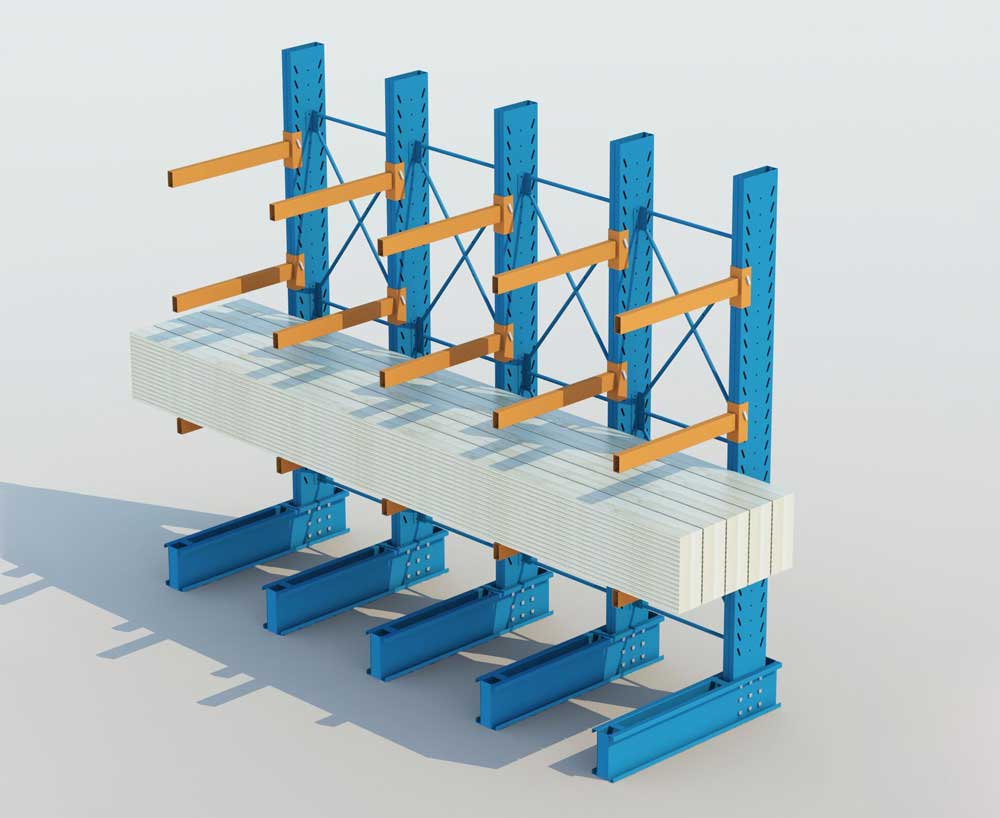

Cantilever racking is a free-standing warehouse rack system that consists of vertical columns, horizontal arms, and bases. The columns are the main support structure of the system, and they are connected by braces to form a rigid frame. The arms are the load-bearing components that extend out from the columns and can be adjusted to different heights and angles. The bases are the foundation of the system and provide stability and balance. The load is stored horizontally on the arms and can be accessed from the front, without any interference from the columns.

Types of Cantilever Racking Systems

There are two main types of cantilever racking systems: single-sided and double-sided. Single-sided cantilever racks have arms on one side of the columns, and they are usually placed against a wall or a fence. Double-sided cantilever racks have arms on both sides of the columns, and they can store goods on the front and the back of the system. Double-sided cantilever racks are more efficient in terms of space utilization, but they also require more aisle space for loading and unloading.

Advantages of Cantilever Racking

Cantilever racking offers several benefits for warehouse management, such as:

Suitable for Heavy Cargo Storage

Cantilever racking is ideal for storing heavy or oversized items that would not fit or be safe on conventional pallet racks. Cantilever racking on the market has arms that can support a maximum load of basically 1 ton (but can be customized for your specific needs in terms of load capacity), and the height and length of the system can be customized to accommodate a variety of sizes and shapes of goods.

Increased Storage Efficiency

Cantilever racking can increase the storage efficiency of a warehouse by maximizing the vertical and horizontal space available. The system can be built to any height and length, depending on the ceiling height and floor space of the warehouse. The system can also be configured to store goods of different lengths and widths on the same rack, by adjusting the arms accordingly. This reduces the waste of space and the need for multiple racks for different types of goods.

Easy Accessibility for Forklifts

Cantilever racking provides easy accessibility for forklifts and other loading equipment. The open-front design of the system eliminates any obstructions or barriers at the front of the racks, allowing forklifts to approach and maneuver around the racks with ease. This improves the handling speed and reduces the labor effort and time required for loading and unloading. It also reduces the risk of accidents or injuries caused by collisions or mishandling.

Versatility in Handling Various Goods

Cantilever racking is versatile in handling various types of goods, such as long, bulky, or irregularly shaped items. The system can store goods that are hard to stack or palletize, such as lumber, pipes, carpets, furniture, or machinery parts. The system can also store goods that are sensitive to temperature or humidity, such as wood, metal, or plastic, by allowing air circulation and ventilation. The system can also store goods that are seasonal or infrequent, such as holiday decorations, sports equipment, or gardening tools, by providing flexible and adjustable storage options.

Choosing the Right Cantilever Racking System for Your Warehouse

Choosing the right cantilever racking system for your warehouse depends on several factors, such as:

Factors to Consider

- The type and size of the goods you want to store. You should consider the length, width, height, weight, and shape of the goods, and how they will be loaded and unloaded. This will determine the dimensions and capacity of the system you need, as well as the number and configuration of the arms.

- The available space and layout of your warehouse. You should consider the floor space, ceiling height, aisle width, and doorways of your warehouse, and how they will affect the installation and operation of the system. This will determine the height and length of the system you can install, as well as the type and orientation of the system (single-sided or double-sided).

- The budget and timeline of your project. You should consider the cost and time involved in purchasing, installing, and maintaining the system, and how they will fit your budget and timeline. This will determine the quality and quantity of the system you can afford, as well as the level of customization and service you can expect.

Customization Options

Cantilever racking systems can be customized to suit your specific needs and preferences, such as:

- The color and finish of the system. You can choose from a variety of colors and finishes for the system, such as powder coating, galvanized, or painted, to match your warehouse aesthetics and branding.

- Cantilever weight capacity. You can decide how much weight your cantilever needs to carry according to your actual situation.

For example, HEDA’s cantilever racking has a wide range of options for weight capacity: 100/200/300/500/800/1000kgs.You can also choose a higher weight capacity, but you also need to pay more money, so depending on your actual storage needs, you can save more money as well as ensure your storage needs. - The accessories and features of the system. You can add various accessories and features to the system, such as end stops, guard rails, decking, or lighting, to enhance the safety, functionality, or appearance of the system.

- The design and engineering of the system. You can consult with professional designers and engineers to design and engineer the system according to your specifications and requirements, such as load capacity, seismic rating, fire rating, or environmental compliance.

Installation and Maintenance Tips for Cantilever Racking

Installing and maintaining a cantilever racking system requires some tips and best practices, such as:

Step-by-Step Installation Guide

- Prepare the site and materials. You should clear the area where you want to install the system, and make sure it is level and stable. You should also check the materials and components of the system, and make sure they are complete and undamaged.

- Assemble the bases and columns. You should start by assembling the bases and columns, and securing them to the floor with bolts and anchors. You should follow the manufacturer’s instructions and specifications, and use the appropriate tools and equipment.

- Attach the braces and arms. You should then attach the braces and arms to the columns, and adjust them to the desired height and angle. You should follow the manufacturer’s instructions and specifications, and use the appropriate tools and equipment.

- Inspect and test the system. You should finally inspect and test the system, and make sure it is stable, sturdy, and aligned. You should also check the load capacity and safety features of the system, and make sure they are adequate and functional.

If your cantilever racks need to carry more than a ton, then the manufacturer will definitely use I-beams to make the arms. Therefore, when you install them, make sure you use a tool such as a crane to assist you in assembling them.

Regular Maintenance Practices

- Clean and inspect the system regularly. You should clean and inspect the system regularly, and remove any dust, dirt, or debris that may accumulate on the system. You should also check for any signs of wear, tear, or damage, such as cracks, bends, or rust, and repair or replace them as soon as possible.

- Follow the loading and unloading guidelines. You should follow the loading and unloading guidelines, and make sure you do not exceed the load capacity or dimensions of the system. You should also use the proper loading and unloading equipment, such as forklifts or cranes, and handle the goods with care and caution.

- Train and educate the staff. You should train and educate the staff, and make sure they are familiar and competent with the system. You should also provide them with the necessary safety equipment and instructions, and enforce the safety rules and regulations.

Conclusion

Cantilever racking is a type of warehouse storage system that is designed to store long, bulky, or irregularly shaped items. It has many advantages, such as suitability for heavy cargo storage, increased storage efficiency, easy accessibility for forklifts, and versatility in handling various goods. Choosing the right cantilever racking system for your warehouse depends on several factors, such as the type and size of the goods, the available space and layout of the warehouse, and the budget and timeline of the project. Installing and maintaining a cantilever racking system requires some tips and best practices, such as following a step-by-step installation guide, cleaning and inspecting the system regularly, following the loading and unloading guidelines, and training and educating the staff.

We hope this article has helped you understand cantilever racking and how it can improve your warehouse management. If you are interested in purchasing a cantilever racking system for your warehouse, please contact us at HEDA. We are a professional rack manufacturer with over 20 years of experience in the industry. We can provide you with high-quality, customized, and affordable cantilever racking solutions that meet your needs and expectations. We also offer free consultation, design, and installation services, as well as after-sales support and warranty. We eagerly anticipate your reply and the opportunity to assist you.

Cantilever racking is a warehouse storage system designed for the efficient storage of long, bulky, or awkward items that are challenging to accommodate on standard pallets. This type of racking is particularly useful for items like lumber, pipes, furniture, and other objects with varying lengths and shapes. Featuring horizontal arms extending from vertical supports, cantilever racking provides a clear space for loading and unloading items.

Widely utilized across various industries, including manufacturing, construction, automotive, retail, and distribution, cantilever racking is a specialized storage solution that ensures the efficient and effective storage of your items.

Cantilever racking is primarily employed for storing non-palletized items like long pipes, sheet metal, and lumber. The spacing between uprights is often wider than that of standard pallets, potentially impacting storage efficiency. While it’s feasible to enhance versatility by adding decking to cantilever arms for pallet support, this application is less common and not the recommended use.

Designed specifically for optimizing the storage of long, bulky, or awkward items, cantilever racking serves as a specialized storage solution. If pallet storage is a requirement, exploring alternatives like selective pallet racking, drive-in racking, or push-back racking may be more suitable. These systems provide enhanced stability, accessibility, and density for palletized items.

There are two main types of cantilever racks: Roll-Formed and structural. Roll-Formed racks are made from lighter gauge steel and are best suited for lighter loads and smaller items. They assemble using boltless pin connectors, making installation and reconfiguration quick and easy. Structural racks are made from heavier gauge steel and can handle larger loads with ease. They consist of vertical columns bolted to a horizontal base with bracing for stability, providing a durable and reliable storage solution.

Within these two types, there are also four subtypes of cantilever racks based on their load capacity: Super Heavy Duty, Heavy Duty, Standard Duty, and Medium Duty. These subtypes can be custom configured to fit your warehouse and material needs. Cantilever racks can also be configured in single-sided or double-sided arrangements depending on your storage space and accessibility requirements.

The answer is yes. Cantilever racking should be bolted down or anchored to the floor for safety reasons.

This can prevent the racking from tipping over or collapsing due to heavy loads or external forces.

Bolting down or anchoring the racking can also improve the stability and rigidity of the system, as well as the alignment of the arms and columns.