Introduction

When we discuss wide span racking, perhaps you are wondering what kind of storage racking is wide span racking? Where does it all appear? And what can it bring you differently?

This article is the answer I want to bring you! Let’s explore wide span racking together!

What is Wide Span Racking?

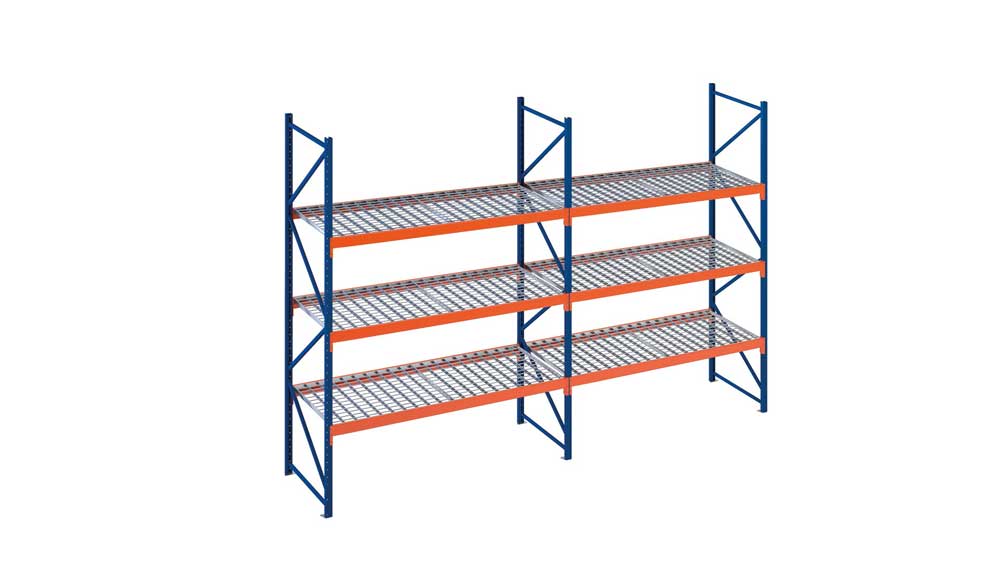

As the name implies, wide span racking has a larger span than conventional racking and can hold more products or accommodate larger products.

In appearance, wide span racking is somewhat similar to boltless racking or pallet racking, but in terms of functionality wide span racking has a different difference.

Wide span racking has a basic load range of 300 kg to 800 kg. HEDA can be customized to give wide span racking a load capacity of up to six tons.

In terms of storage space, wide span racking usually has a length of 90 cm to 300 cm and a depth of 30 cm to 120 cm. As a result, wide span racking is longer and deeper than normal racking, and this results in more storage space.

However, it is worth mentioning that wide span racking can only be loaded manually, so it differs from pallet racking in this respect.

Benefits of Wide Span Racking

So wide span racking is a special kind of racking, what needs does it exist to fulfill the users? And what benefits can it bring to you?

Now I will tell you all the wonderful things about it.

Versatile

The storage space of wide span racking can accommodate most items that may not fit well in standard racking, but are perfectly accommodated in wide span racking.

This is all thanks to the design of wide span racking, which makes up for the inability of conventional racking to store slightly larger items and the inability of industrial racking to store goods of different shapes.

Of course, it should be noted that each wide span racking has a different load-bearing design, which requires strict compliance with the manufacturer’s weight limitations.

Accessible storage

The wide span racking has an open shelf design, which means that you can access goods from the front and back of the shelf, which is very convenient for the user and gives a lot of freedom in the use of the storage space.

In addition, if you have a large need for wide span racking to store large quantities of goods and access them frequently, you can also use wide span racking in conjunction with a labeling system that automatically retrieves goods by scanning the labels, which gives you a great deal of fast and hassle-free access.

Modular components

The wide span racking product is designed with no bolts and modular components, which means you can easily put it together. This way you don’t have to worry about missing any screws along the way and you can reconfigure the wide span racking to meet your new needs later on.

I would like to add that if your wide span racking has a heavy cargo load, your wide span racking may not be able to be a boltless design, it all depends on your actual needs.

Sturdy and durable

Wide span racking generally uses steel as the raw material for manufacturing, and since the load-bearing setup of wide span racking is basically to face medium or heavy goods, the thickness of the steel of the uprights and beams is not bad.

Usually, the thickness of steel for wide span racking is between 9mm to 30mm for uprights and 6.5mm to 20mm for beams. Of course, the actual purchase of wide span racking will vary according to your load-bearing needs and price, and the difference between different materials will also have a thickness difference, which we need to understand.

Customization

Customization options for wide span racking are also plentiful. Take our brand HEDA for example, we can customize everything about wide span racking. This includes but is not limited to, the material of the uprights and beams, the type of laminate, the size of the racking, the color of the racking, and more.

Components of Wide Span Racking

Next, let’s discuss what wide span racking is usually made up of, and when you understand it I think you’ll have a clearer idea of what you’re looking for when purchasing or reconfiguring wide span racking.

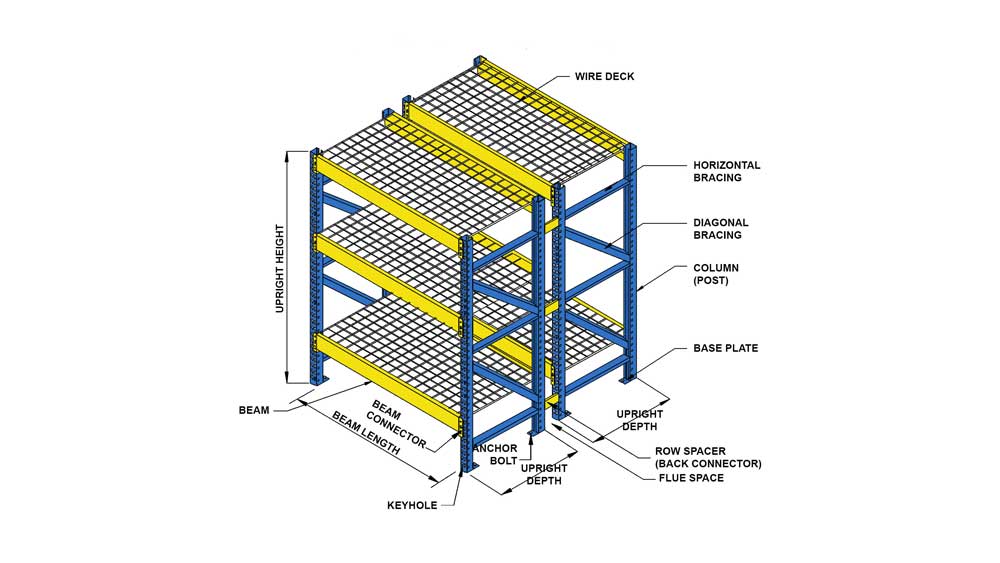

Upright

Uprights are the main support structure of wide span racking. Generally speaking, there are four uprights, but some wide span racking uprights are modular in design, the front and rear uprights are welded together by diagonal braces, so this kind of uprights we call an upright frame. When you receive the goods this kind is only two upright frames instead of four uprights and several diagonal bracing.

Beam

The beam is a key component that connects the left and right uprights or upright rows and provides a stress point for the laminate.

The beams are made of the same material as the uprights, usually steel. Of course, when customizing the racks at the manufacturer, you can also change the material of beams, columns, shelves, etc. according to the needs of the environment, for example, stainless steel would be better for use in cold storage areas.

Layer

In wide span racking, the role of the layer is to support goods, separate vertical spaces, enhance structural strength, and allow staff to operate easily.

The material of the layer is also different, usually, the laminate is made of steel plate, but according to the different needs of each person, you can also choose plastic, metal mesh plywood, and other materials.

Safety accessories

Some of the common safety accessories we see are crash posts, safety rails, and post protectors.

Diagonal bracing

This component usually exists in two forms. One is a separate component that is attached to the side of the wide span racking (between the two rights) with bolts or other connectors.

The other is that some wide span racking will have the diagonal braces welded into the uprights to form an upright frame, so there is no separate diagonal brace assembly in this case.

Application of wide span racking

Having said that, the advantages and components of wide span racking. We might be wondering where wide span racking should be able to be used. If you have similar questions, why don’t you pay attention to us and continue reading?

Warehousing and logistics centers

The wide span racking design is very good for storing large items or quantities of items, and these scenarios are perfectly suited for warehouses and logistics centers.

Retail stores

In stores selling large items such as household goods, sports equipment or bicycles. These goods are large but not heavy goods, and it takes up too much space to display them on the floor of the store, so the application of wide span racking can be a very good way to meet the needs of displaying and storing these goods.

Factory

In a factory setting, wide span racking can be used to meet some of the specific needs of a factory. For example, storing tools, parts to be installed, finished products, etc. The open design of wide span racking is very easy for workers to use and access the items.

Archives or libraries

Wide span racking is ideal for archives or libraries where large amounts of paper are stored. The ruggedness and space of wide span racking provide a good storage environment for paper items, and users can use wide span racking with a labeling system for easy management and quick retrieval.

Garage

In fact, in our personal use scenario, wide span racking is perfect for a space like a garage. In the United States and some areas, many families have their garages, and they store machinery and tools in them. In this case, everyone will need something that can keep things neat and organized, so wide span racking is a unique existence, and wide span racking is easy to assemble the advantages of is more convenient for our personal use.

Conclusion

Maybe you’ve gained a new understanding of wide span racking, or maybe our article didn’t answer the question you’re struggling with right now. But I’m always here, HEDA is always here, and you’re always welcome to contact us!

Last, let me introduce myself again, my name is Stefan, and I am the CEO of a professional racking manufacturer from China, if you need a reliable racking supplier, why don’t you try to contact me?