All goods in the world follow a standard specification and size, and warehouse racks are no exception. However, many people often wonder: do warehouse racks also have standard dimensions?

In my view, within industry practice, there are indeed some commonly used “standardized” dimensions, which are designed based on mainstream pallet specifications and storage requirements.

However, strictly speaking, the concept of “standard dimensions for warehouse racks” is not entirely accurate. Rack dimensions typically need to be customized according to specific storage needs, warehouse layouts, and pallet specifications.

Next, I will delve deeper into the topic of “standard warehouse shelf dimensions.” By the end of this article, I believe you will gain a lot more insights!

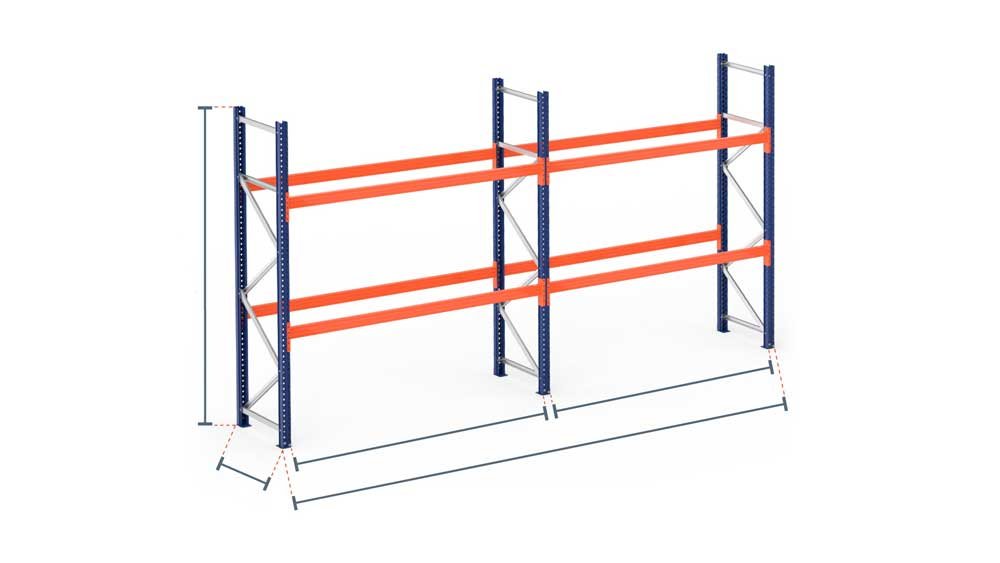

Standard Dimensions of Pallet Racks

The standard dimensions of pallet racks are typically designed based on pallet specifications, warehouse space, and storage needs. As a result, there is no universally “standard” size globally. However, the industry does have some commonly used size ranges that are widely adopted for storing standard pallets.

Key Components of Pallet Rack Dimensions

Pallet rack dimensions generally include three key parameters:

- Height (H): The total height of the rack’s uprights.

- Beam Length (L): The length of the rack beams, usually determined by the number of pallets stored per level.

- Rack Depth (D): The depth of the rack from front to back, matching the width of the pallet.

Common Pallet Specifications and Rack Designs

Pallet size is the core factor in determining rack specifications. Below are rack designs for common pallet sizes:

European Standard Pallet (1200×800mm, EUR Pallet)

For 2 pallets per level:

- Beam Length (L): 2700mm

- Rack Depth (D): 800mm or 900mm

For 3 pallets per level:

- Beam Length (L): 3600mm

- Rack Depth (D): 800mm or 900mm

North American Standard Pallet (1200×1000mm)

For 2 pallets per level:

- Beam Length (L): 2700mm

- Rack Depth (D): 1000mm or 1100mm

For 3 pallets per level:

- Beam Length (L): 3600mm

- Rack Depth (D): 1000mm or 1100mm

Asian Standard Pallet (1100×1100mm)

For 2 pallets per level:

- Beam Length (L): 2400mm

- Rack Depth (D): 1100mm

For 3 pallets per level:

- Beam Length (L): 3600mm

- Rack Depth (D): 1100mm

Rack Height (H)

Rack height is generally determined by the net height of the warehouse and the lifting capacity of forklifts. Common height ranges include:

- Low racks: 2000-4000mm

- Medium-to-high racks: 5000-8000 mm

- High racks: 9000-12000 mm (commonly used in high-density storage systems)

Adjustable Beam Levels

The beam levels of pallet racks are usually adjustable at regular intervals to accommodate different goods’ heights:

- Common adjustment intervals: 50mm, 75mm

Standard Tolerances and Regulations

International standards and regional guidelines impose specific requirements on pallet rack design. Examples include:

- European Standard EN 15620:

- Tolerances and gaps (e.g., spacing between pallets and rack beams).

- American Standard ANSI MH16.1:

- General provisions for rack strength, stability, and dimensions.

The Impact of Pallet Dimensions on Rack Design

Pallet dimensions have a direct impact on rack design, as the primary purpose of racks is to provide safe and efficient storage space for pallets. The size, weight, and storage requirements of pallets determine the dimensions, structure, and layout of racks.

Beam Length

The length of rack beams is determined by the length and quantity of pallets.

- Pallet Dimensions: The width (short side) of the pallet is typically placed parallel to the beam direction.

- Design Principles: The beam length must accommodate the pallets and allow for clearance to ensure safety and ease of operation.

- Clearance between pallets: 50-100mm.

- Clearance between pallets and rack uprights: 75-100mm.

Examples:

- European Standard Pallet (1200×800mm):

- For 2 pallets: Beam length ~2700mm (1200×2 + 100×3).

- For 3 pallets: Beam length ~3600mm (1200×3 + 100×4).

- North American Standard Pallet (1200×1000mm):

- For 2 pallets: Beam length ~2700mm.

- For 3 pallets: Beam length ~3600mm.

Rack Depth

The depth of the rack is determined by the depth (long side) of the pallet.

- Single-Deep Rack: The rack depth is typically equal to or slightly larger than the pallet depth.

- Example: For a pallet depth of 1200mm, the rack depth is 1100-1200mm.

- Double-Deep Rack: Designed to store two pallets back-to-back, with a depth twice that of a single pallet. Backstops are required to prevent pallets from sliding out.

Design Principles:

- The rack depth should be 50-100mm shorter than the pallet depth to avoid overhang.

- If using cantilevered pallets, additional front and rear support bars are required.

Rack Height

The height of the pallet (including the goods) determines the height of each level and the overall rack height.

- Level Height Design:

- Level height must exceed the pallet height, with an operational clearance of 100-150mm.

- For pallets of uniform height, standardized level heights can be used. For varying pallet heights, custom designs are required.

- Total Height:

- Limited by the net height of the warehouse and the lifting capacity of forklifts.

- High racks are typically designed to be within 12,000mm for safety and stability.

Storage Density and Space Utilization

Pallet dimensions directly affect storage density and space utilization:

- Larger Pallets: Reduce the number of pallets stored per level but are suitable for heavy or bulky goods.

- Smaller Pallets: Increase the number of pallets stored per level but require precise clearance designs to avoid wasted space.

Pallet Weight and Rack Load Capacity

Pallet dimensions are often correlated with load capacity, influencing the structural strength of racks:

- Beam Load Capacity: Must support the total weight of pallets on a single level.

- Upright Load Capacity: Must support the total weight of the rack, including a safety factor.

Forklift Operation and Aisle Design

Pallet dimensions affect the turning radius of forklifts and the width of rack aisles:

- Formula: Pallet width + clearance between pallets + operational allowance = aisle width.

- Standard narrow aisle width for pallet racks: Approximately 2.8-3.6 meters.

Dimensional Characteristics of Different Rack Types

Warehouse racks vary in size characteristics based on their application scenarios, the nature of stored goods, and operational methods. Below is an overview of the key types and their dimensional features:

Selective Pallet Racks

- Application: The most common rack type, ideal for pallet storage with direct forklift access.

- Dimensional Features:

- Beam Length: Designed based on pallet count, commonly 2400mm (for 2 pallets) or 2700mm (for 3 pallets).

- Rack Depth: Typically 800mm–1100mm, matching pallet depth.

- Height Range: Can be designed from low levels (2000mm) to high levels (12000mm).

- Advantages: Simple structure, high flexibility, but lower storage density.

Drive-In Racks

- Application: Suitable for high-density storage of large quantities of uniform goods.

- Dimensional Features:

- Rack Depth: Depends on storage rows, typically 5–10 pallet positions deep.

- Rack Height: Usually 4000mm–8000mm, limited by forklift lift capacity.

- Aisle Width: Slightly wider than pallet width, typically 1350mm–1500mm.

- Advantages: High storage density, but follows the “Last In, First Out” (LIFO) principle.

Gravity Flow Racks

- Application: Facilitates “First In, First Out” (FIFO) storage using gravity-fed rollers, ideal for fast-turnover goods.

- Dimensional Features:

- Rack Depth: Accommodates 5–20 pallets deep, depending on roller design.

- Roller Width: Slightly wider than pallet width, typically 1000mm–1200mm.

- Height Range: Generally 4000mm–7000mm, influenced by roller slope (3%-5%) and number of levels.

- Advantages: High retrieval efficiency, but higher initial cost.

Very Narrow Aisle (VNA) Racks

- Application: Used with narrow-aisle forklifts for high-density storage.

- Dimensional Features:

- Beam Length: Similar to selective racks, typically 2400mm–2700mm.

- Rack Height: Can reach 10000 mm–15000mm.

- Aisle Width: About 1.6m–2.0m, narrower than standard forklift aisles.

- Advantages: High space utilization but requires specialized narrow-aisle forklifts.

Double-Deep Racks

- Application: Extends selective racks by adding an additional pallet depth to increase storage density.

- Dimensional Features:

- Rack Depth: Two rows of pallets, depth typically 2200mm–2400mm.

- Beam Length: Similar to single-row storage, usually 2400mm–2700mm.

- Height Range: Typically 6000mm–12000mm.

- Advantages: Higher storage density but requires double-deep forklifts for access.

Cantilever Racks

- Application: Specifically designed for long items such as pipes and lumber.

- Dimensional Features:

- Rack Height: Commonly 3000mm–6000mm, customizable based on item length.

- Arm Length: Typically 600mm–2000mm, designed to suit item dimensions.

- Shelf Spacing: Adjustable based on item thickness.

- Advantages: Ideal for storing long, irregularly shaped goods; highly adaptable structure.

Mezzanine Racks

- Application: Extends warehouse vertical space with multi-level structures.

- Dimensional Features:

- Floor Height: Typically 2500mm–3000mm, based on manual or equipment-based operations.

- Rack Height: Depends on warehouse net height, typically 5000 mm–10000 mm.

- Aisle Width: Generally 800mm–1200mm, based on operational requirements.

- Advantages: Maximizes space utilization and supports manual or mechanical storage.

Automated Storage and Retrieval Systems (AS/RS)

- Application: Integrated with automated equipment for efficient storage and retrieval.

- Dimensional Features:

- Rack Height: Can exceed 20 meters, utilizing vertical space fully.

- Rack Depth: Single-deep or double-deep designs, typically 800mm–2400mm.

- Aisle Width: Determined by stacker crane design, typically 1.5m–2.5m.

- Advantages: High efficiency and intelligence, but with higher investment costs.

International Standards and Regional Differences

In warehouse racking design and use, international standards and regional differences play a significant role in determining racking dimensions, design specifications, and manufacturing standards. These standards ensure the safety, functionality, and compatibility of racking systems. However, due to differences in logistics models, pallet standards, and regulations across regions, there are notable regional variations. Here is a detailed analysis:

International Standards

ISO Standards (International Organization for Standardization)

ISO provides globally recognized standards for racking and pallet design, manufacturing, and testing requirements. Key ISO standards include:

- ISO 8611: Pallet strength and performance standards.

- ISO 6780: International pallet dimension standards, with common specifications such as:

- 1200×1000mm (common in Europe and Asia)

- 1200×800mm (European standard pallet)

- 1219×1016mm (North American standard pallet)

- ISO 11660: Racking safety operation and labeling requirements.

These standards form the foundation for racking designs, ensuring they meet international logistics needs.

FEM Standards (European Material Handling Federation)

FEM is widely adopted in Europe and includes technical standards for racking structures, testing, and safety requirements:

- FEM 10.2.02: Design and safety specifications for pallet racking.

- FEM 10.3.01: Static and dynamic load calculation methods for racking.

These standards emphasize racking stability, seismic resistance, and material strength.

Regional Differences

Europe

- Pallet Standards:

- Main pallet size: 1200×800mm (EURO pallet), which corresponds to beam lengths of around 2700mm.

- Regulations and Safety Standards:

- Strong adherence to FEM and ISO standards, with strict load and seismic regulations.

- Design Characteristics:

- Emphasis on eco-friendly materials, with racks commonly made of recyclable steel.

- Flexible sizing to suit various industry needs.

North America

- Pallet Standards:

- Main pallet size: 48×40 inches (1219×1016mm), with common beam lengths of 2700 mm or 3600mm.

- Regulations and Safety Standards:

- Follows RMI (Rack Manufacturers Institute) standards, focusing on racking’s seismic and load-bearing tests, especially in high-seismic risk zones.

- Design Characteristics:

- Larger racking sizes for large-scale, high-density storage.

- Wider aisle widths designed for North American forklift operations.

Asia

- Pallet Standards:

- Common pallet sizes: 1200×1000mm or 1100×1100mm (used for international trade).

- Regulations and Safety Standards:

- Reference ISO and FEM standards, but with greater flexibility in implementation.

- Design Characteristics:

- High space utilization, with racks often reaching heights of 10-12 meters.

- Narrow aisle designs are common, particularly for narrow-aisle racking systems.

Australia

- Pallet Standards:

- Common pallet size: 1165×1165 mm (Australian standard pallet).

- Regulations and Safety Standards:

- Follows AS 4084 (Australian pallet racking standard).

- Design Characteristics:

- Medium racking height (6-8 meters) with an emphasis on durability and corrosion resistance due to the local climate.

Middle East and Africa

- Pallet Standards:

- No uniform specification; commonly use European and North American pallets.

- Regulations and Safety Standards:

- Safety standards generally reference European and North American guidelines, but enforcement can be less stringent.

- Design Characteristics:

- Heavy-duty and high-heat-resistant designs to accommodate the extreme local climate conditions.

Conclusion

Talking about it now, I think you should already have more knowledge about standard warehouse shelving sizes, and if you are interested in this topic, then this article should also give you a comprehensive understanding.

In fact, warehouse shelving is a very interesting product. My colleagues and I have been in this industry for more than twenty years, we love this industry, so if you have more questions and needs for warehouse shelving, you are welcome to contact us!